Introduction

As a seasoned professional in the PET blowing machine industry, I’ve witnessed firsthand the remarkable advancements and benefits that these machines offer. In this comprehensive article, I will delve into the numerous advantages and applications of PET blowing machines in the production of plastic bottles across various industries.

Understanding PET Blowing Machines

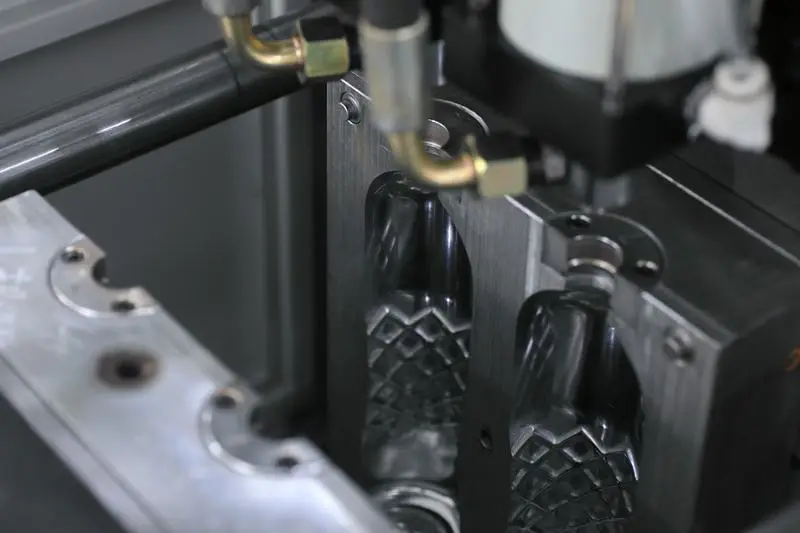

Before delving into their advantages, it’s crucial to understand what PET blowing machines are and how they function. PET blowing machines are specialized equipment used to produce plastic bottles through a process called blow molding. These machines utilize Polyethylene Terephthalate (PET) as the primary material, which is heated and molded into the desired bottle shape.

Advantages of PET Blowing Machines

1. Flexibility in Design

One of the primary advantages of PET blowing machines is their flexibility in design. These machines can produce bottles of various shapes, sizes, and designs, catering to the diverse needs of different industries. Whether it’s a sleek, modern bottle for the beverage industry or a durable, functional container for the pharmaceutical sector, PET blowing machines can adapt to meet the specifications of any project.

2. Cost-Effectiveness

PET blowing machines offer significant cost savings compared to traditional manufacturing methods. The efficiency of the blow molding process, coupled with the ability to produce large quantities of bottles in a relatively short timeframe, results in reduced production costs per unit. This cost-effectiveness makes PET blowing machines an attractive option for businesses looking to optimize their manufacturing processes while maintaining high-quality standards.

3. Lightweight and Durable Products

PET bottles produced using blowing machines are lightweight yet incredibly durable, making them ideal for packaging various liquids and products. Whether it’s carbonated beverages, household cleaners, or personal care products, PET bottles offer excellent resistance to impact, ensuring the safe transport and storage of contents. Additionally, their lightweight nature reduces shipping costs and environmental impact, making them a preferred choice for eco-conscious consumers and businesses alike.

4. Customization Options

PET blowing machines enable customization at every stage of the production process. From choosing the bottle design and size to incorporating brand-specific colors and logos, businesses have the flexibility to create unique packaging solutions that stand out in the market. This customization not only enhances brand visibility but also allows companies to tailor their products to specific consumer preferences, ultimately driving sales and brand loyalty.

5. High Production Efficiency

With advancements in technology, modern PET blowing machines boast high production efficiency, allowing manufacturers to meet demanding production schedules without compromising on quality. These machines feature automated processes, precise controls, and rapid cycle times, resulting in consistent output and minimal downtime. As a result, businesses can streamline their operations, increase output capacity, and respond quickly to market demands, ultimately improving their competitiveness and profitability.

6. Sustainable Solutions

In an era of increasing environmental awareness, PET blowing machines offer sustainable solutions for packaging needs. PET is a fully recyclable material, and PET bottles can be recycled and repurposed multiple times without compromising their quality. Additionally, the lightweight nature of PET bottles reduces carbon emissions during transportation, further contributing to environmental conservation efforts. By investing in PET blowing machines, businesses can align with sustainable practices, reduce their carbon footprint, and appeal to environmentally-conscious consumers.

Applications of PET Blowing Machines

The versatility of PET blowing machines extends across various industries, including:

- Beverage Industry: Producing bottles for water, carbonated drinks, juices, and alcoholic beverages.

- Food Industry: Packaging condiments, sauces, oils, and other food products.

- Pharmaceutical Industry: Manufacturing containers for medicines, vitamins, and healthcare products.

- Personal Care Industry: Bottling shampoos, lotions, soaps, and beauty products.

- Household and Cleaning Products: Packaging detergents, cleaners, and disinfectants.

Conclusion

In conclusion, PET blowing machines offer a myriad of advantages for businesses involved in bottle manufacturing. From flexibility in design and cost-effectiveness to lightweight durability and sustainability, these machines have revolutionized the packaging industry. With their ability to produce high-quality bottles efficiently and sustainably, PET blowing machines are indispensable tools for businesses looking to stay competitive in today’s dynamic market.

If you’re interested in incorporating PET blowing machines into your production process or have any inquiries, feel free to reach out to us for a quote here or contact us here. Let us help you revolutionize your packaging solutions today!