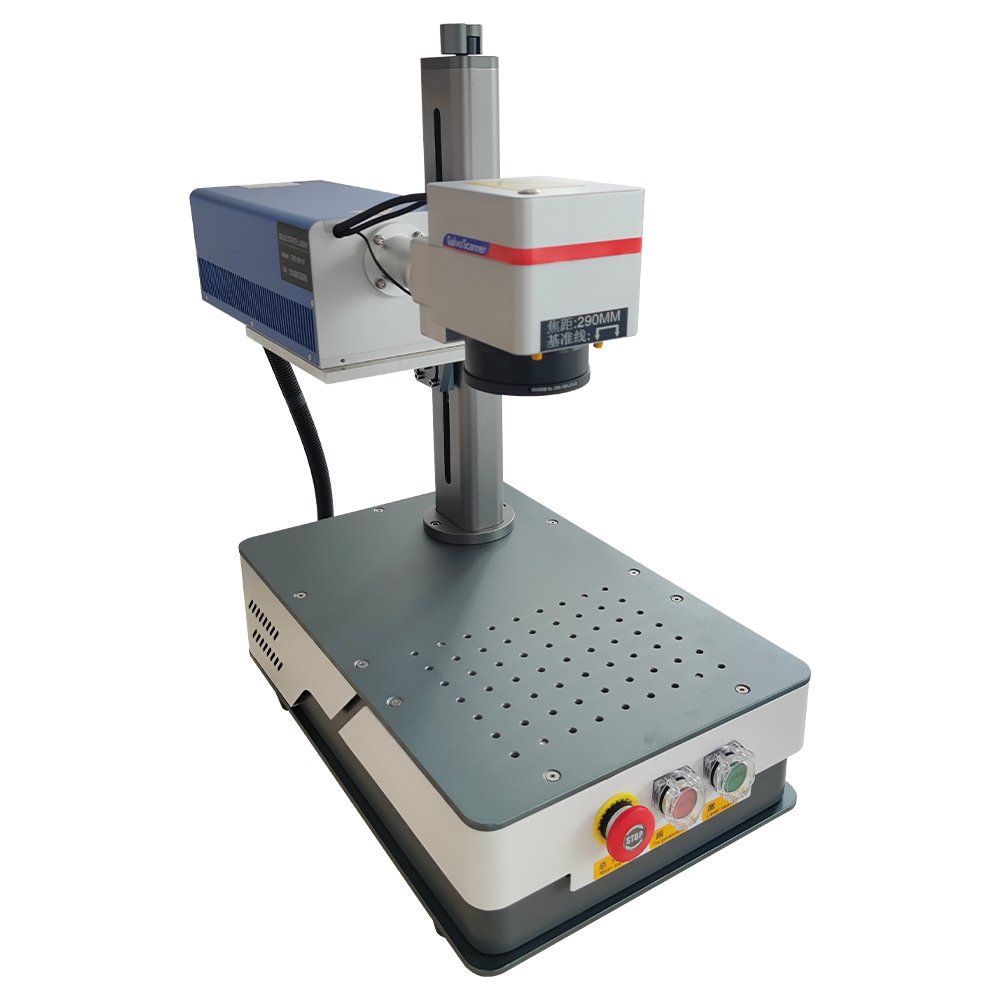

A Desktop UV Laser Marking Machine is a compact and versatile tool used for high-precision marking, engraving, and coding on a wide range of materials. Its applications span various industries due to its ability to produce clean, permanent, and high-contrast marks without damaging the material. Below are some key applications:

1. Electronics Industry

PCB Marking: Marking serial numbers, barcodes, and logos on printed circuit boards (PCBs).

Microchip Engraving: Permanent marking on microchips and semiconductor components.

Cable and Wire Marking: Labeling cables and wires for identification.

2. Medical Devices

Surgical Instruments: Engraving identification codes, logos, or batch numbers on surgical tools.

Medical Implants: Marking serial numbers or tracking information on implants.

Packaging: High-precision marking on medical packaging for traceability.

3. Jewelry and Luxury Goods

Personalization: Engraving names, dates, or designs on jewelry, watches, and accessories.

Branding: Adding logos or serial numbers to luxury items for authenticity.

4. Packaging and Labeling

Plastic Packaging: Marking expiration dates, batch numbers, or barcodes on plastic containers.

Glass Bottles: Engraving logos or labels on glass products without causing cracks.

Cosmetic Packaging: Adding branding or product information on cosmetic containers.

5. Automotive Industry

Component Marking: Engraving part numbers, barcodes, or logos on automotive components.

Tire Marking: Adding identification codes or safety information on tires.

6. Aerospace Industry

Aircraft Parts: Marking serial numbers, safety information, or logos on aerospace components.

Tooling: Engraving identification codes on tools and equipment.

7. Consumer Goods

Plastic Products: Marking logos, QR codes, or product information on plastic items.

Gift Items: Personalizing promotional items or gifts with text or designs.

8. Security and Traceability

Anti-Counterfeiting: Adding holographic marks, QR codes, or serial numbers for product authentication.

Traceability: Marking unique identifiers for tracking products through the supply chain.

9. Art and Design

Custom Engraving: Creating intricate designs or patterns on wood, acrylic, or glass.

Prototyping: Marking or engraving prototypes for testing and validation.

Advantages of UV Laser Marking:

High Precision: Ideal for fine details and small components.

Non-Contact Process: No physical damage to the material.

Versatility: Works on a wide range of materials, including plastics, glass, metals, and ceramics.

Permanent Marks: Resistant to wear, fading, or tampering.

Environmentally Friendly: No inks or chemicals are required.

- Materials Suitable for UV Laser Marking:

- Plastics (e.g., ABS, PVC, polycarbonate)

- Glass and ceramics

- Metals (e.g., stainless steel, aluminum)

- Paper and cardboard

- Leather and fabrics

A desktop UV laser marking machine is an essential tool for industries requiring high-quality, durable, and precise marking solutions.

Parameter Table:

| Model | VK-UV20 (30/50) |

| Light source | UV laser |

| Power | 20W, 30W, 50W |

| Line width | 0.02mm |

| Marking speed | 7000mm/s |

| Positioning accuracy | ± 0.01mm |

| The scope of work is | 110 * 110, 150*150, 175,175mm |

| Working power supply | 220V/50HZ |