Laser engraving machines have revolutionized the world of material processing, offering unparalleled precision, versatility, and efficiency. These machines utilize focused laser beams to etch, mark, or cut a wide range of materials, making them indispensable tools in industries ranging from manufacturing to arts and crafts. But what exactly can a laser engraving machine work with? In this blog, we’ll explore the diverse materials that laser engraving machines can process, highlighting their applications and the unique benefits they offer.

1. Wood

Wood is one of the most popular materials for laser engraving due to its natural texture and ease of processing. Laser engraving machines can create intricate designs, patterns, and text on various types of wood, including:

Hardwoods: Oak, maple, walnut, and cherry are ideal for detailed engravings and high-contrast markings.

Softwoods: Pine and cedar are easier to engrave but may require lower power settings to avoid excessive burning.

Plywood and MDF: These engineered wood products are also compatible, though the quality of engraving depends on the adhesive used in their construction.

Applications: Custom signage, furniture decoration, artistic designs, and personalized gifts.

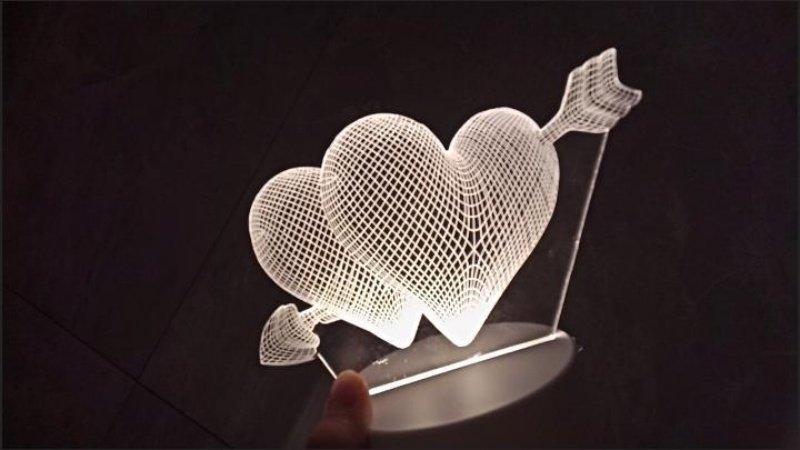

2. Acrylic

Acrylic, also known as Plexiglas, is a favorite material for laser engraving because it produces a smooth, polished finish. When engraved, acrylic creates a frosted effect that contrasts beautifully with the surrounding material.

Cast Acrylic: Ideal for engraving, as it produces a uniform frosted appearance.

Extruded Acrylic: Better suited for cutting but can still be engraved with care.

Applications: Awards, trophies, signage, and decorative items.

3. Metals

While metals are generally more challenging to engrave due to their reflective and conductive properties, modern laser engraving machines, particularly fiber lasers, excel at marking and engraving metal surfaces. Common metals include:

Stainless Steel: Often used for industrial labels, serial numbers, and branding.

Aluminum Popular for aerospace components, electronic housings, and promotional items.

Brass and Copper: Frequently used for jewelry, nameplates, and artistic engravings.

Titanium: Commonly engraved for medical devices and high-performance industrial parts.

Applications: Industrial part marking, jewelry customization, and branding.

4. Plastics

Laser engraving machines can process a wide variety of plastics, though the results depend on the type of plastic and its composition.

ABS: Engraves well but may produce fumes, so proper ventilation is required.

Polycarbonate: Not ideal for CO2 lasers due to its tendency to discolor, but fiber lasers can mark it effectively.

PET and PVC: Suitable for engraving, though PVC releases harmful chlorine gas and should be avoided.

Delrin: A durable plastic that engraves cleanly, often used for mechanical parts.

Applications: Keychains, electronic enclosures, and industrial labels.

5. Glass

Laser engraving on glass creates a frosted, elegant appearance. However, it requires careful control of power and speed to avoid cracking.

Borosilicate Glass: Commonly used for laboratory equipment and kitchenware.

Soda-Lime Glass: Found in windows, bottles, and decorative items.

Crystal: Produces stunning engravings for high-end gifts and awards.

Applications: Wine glasses, mirrors, and decorative art pieces.

6. Leather

Laser engraving on leather produces a burnt, vintage look that is highly sought after for personalized items.

Natural Leather: Engraves beautifully, with the ability to create intricate designs.

Synthetic Leather: Can also be engraved but may produce less consistent results.

Applications: Wallets, belts, bags, and custom footwear.

7. Paper and Cardboard

Laser engraving machines can cut and engrave paper and cardboard with incredible precision, making them ideal for intricate designs.

Cardstock: Perfect for creating detailed invitations and packaging prototypes.

Kraft Paper: Often used for eco-friendly packaging and artistic projects.

Applications: Greeting cards, packaging, and model-making.

8. Fabric

Laser engraving can be used to cut and mark fabrics, offering a clean, sealed edge that prevents fraying.

Cotton: Engraves well for decorative patterns.

Polyester: Requires careful settings to avoid melting.

Denim: Popular for creating distApplications: Fashion design, home textiles, and promotional items.

9. Stone and Ceramics

Laser engraving on stone and ceramics produces a permanent, high-contrast mark that is both durable and aesthetically pleasing.

Granite and Marble: Often used for memorials, plaques, and decorative items.

Ceramic Tiles: Ideal for custom kitchen backsplashes and artistic projects.

Slate: Perfect for rustic-style engravings and coasters.

Applications: Memorial stones, personalized gifts, and home décor.

10. Rubber

Laser engraving on rubber is commonly used to create stamps and molds.

Natural Rubber: Engraves cleanly for stamp production.

Silicone Rubber: Can also be engraved but requires specific settings.

Applications: Custom stamps, gaskets, and industrial molds.

11. Food

Yes, laser engraving can even be used on certain foods! While not as common, it’s a growing trend for customization and branding.

Fruits and Vegetables: Apples, potatoes, and cucumbers can be engraved for decorative purposes.

Baked Goods:Cookies and bread can be marked with logos or messages.

Applications: Food branding, event catering, and novelty items.

Conclusion

Laser engraving machines are incredibly versatile tools capable of processing a vast array of materials. From wood and acrylic to metals and fabrics, the possibilities are nearly endless. Whether you’re an artist, engineer, or entrepreneur, understanding the capabilities of laser engraving can open up new creative and professional opportunities. Always remember to adjust the laser settings—such as power, speed, and focus—to suit the specific material you’re working with, and prioritize safety by using proper ventilation and protective equipment.

With the right machine and a bit of creativity, laser engraving can transform ordinary materials into extraordinary works of art and functional products. So, what will you create next?