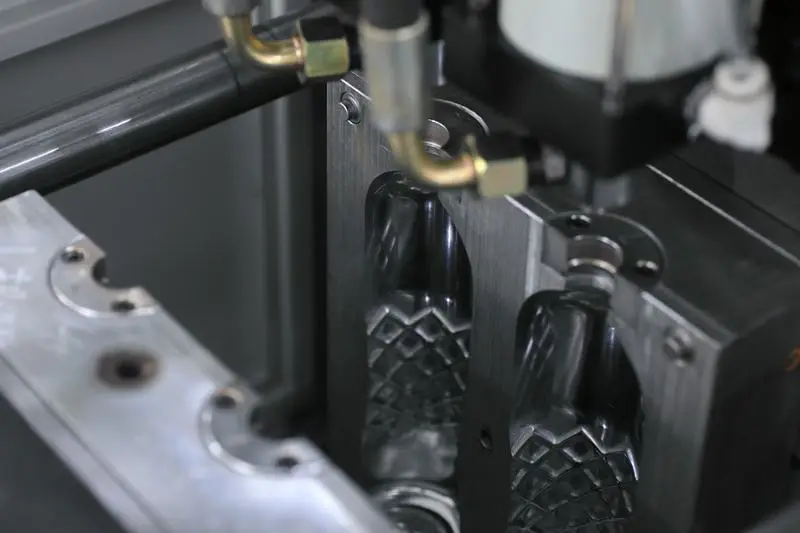

10L fully automatic bottle blow molding machine

Classification Parameter Sheet Classification Items Units VK-A10L VK-A10L/2 Molding Group Specifications Mold Clamping Moment KN 500 500 Mold Stroke mm 270 270 Tie Rod Stroke mm 550 550 Bottom Mold Stroke mm 50 50 Cavity Spacing mm 270 270 Number Of Cavities pcs 1 2 Bottle Type Specifications Theoretical Yield bph 500-700 900-1200 Bottle Maximum […]

10L fully automatic bottle blow molding machine Read More »